PID Control Temperature Sensors & Controllers

A PID (Proportional-Integral-Derivative) temperature controller is a device that uses a closed-loop feedback system to maintain a precise temperature setpoint by continuously adjusting the output based on the error, past errors, and the rate of change of the error. This is achieved through three control actions: proportional (P), integral (I), and derivative (D). A temperature sensor, such as a thermocouple or RTD, provides input to the PID controller, which compares the actual temperature to the desired setpoint.

Here's a more detailed breakdown:

1. PID Controller:

A PID controller is a feedback control loop mechanism that uses three control actions:

proportional (P), integral (I), and derivative (D).

Function:

It continuously adjusts the output based on the error between the desired setpoint and the

actual process value (e.g., temperature).

Output:

The controller's output is then sent to a control element, such as a heater or fan, to

adjust the temperature.

2. Temperature Sensor:

A temperature sensor is a device that detects and measures the temperature of a process.

Types: Common types of temperature sensors include thermocouples and RTDs.

Function: The sensor provides a signal to the PID controller that represents the

current temperature.

Product Reviews

"Absolutely love this product! The quality exceeded my expectations, and it works exactly as described. Fast delivery and great customer service made the whole experience even better. Highly recommend to anyone looking for reliability and value!"

Posted by Anonymous on 08/1/25

"This product is fantastic! It's well-made, easy to use, and delivers great results. I'm very satisfied with my purchase and would definitely recommend it to others!"

Posted by Anonymous on 13/5/25

"We are thrilled with the product! It’s high-quality, user-friendly, and truly delivers on its promises. A great choice for anyone looking for reliability and performance. Highly recommended!"

Posted by Anonymous on 30/10/25Leave a Review

Our Sensors & Related Products

PID Control Temperature Sensor

TEMPERATURE SENSORS

PROXIMITY SENSORS

PHOTO SENSORS

LASER SENSORS

ANALOG SENSOR

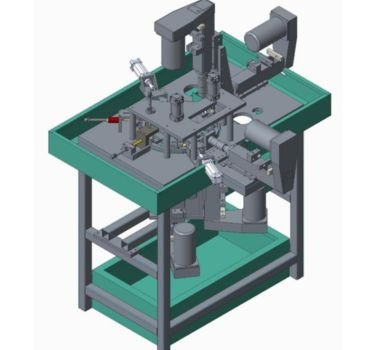

FORGING PRESS